Tooling can make or break a job. Whether you’re a Rental House, Dealer, a Contractor, or a DIY user, you’ll want to make sure you understand a few basic things about the tooling required for polishing concrete to ensure the right finish.

In this blog we will be discussing the tooling we have available at Bartell Global. Although we will be talking specifically about the type of tooling we offer, we are not saying that if you choose to use other tooling that you won’t be able to achieve the finish you’re looking for. Having said that, we can speak with full confidence and knowledge of the high quality and effectiveness of our tooling. There is a reason we have chosen the specific tooling we offer and recommend, so that we can be confident that our customers will be happy with the products, as well as the results.

BONDS

Bond refers to the metal or material that holds or binds the diamond pieces to the segment.

There are 4 different types of Bonds, X-Soft, Soft, Medium, and Hard.

X-Soft: The metallic powder in the sintered segment wears away very quickly, releasing dull diamond crystals, and exposing new abrasive crystals. For the hardest concrete surfaces.

Soft: The metallic powder in the sintered segment wears away very quickly, releasing dull diamond crystals, and exposing new abrasive crystals. Best used for hard concrete surfaces.

Medium: Metal bond strength between soft and hard. Most commonly used.

Hard: The bond of metallic powder in the segment wears away slowly. Best for soft concrete surfaces.

The reason you want to use a Soft Bond on Hard Concrete is so that the abrasive diamonds are exposed more quickly and efficiently so they are able to grind the surface better. If you use a hard bond on hard concrete, then the tooling will “glaze over” and won’t grind. For soft concrete, you want a harder bond so the diamonds don’t become too exposed too quickly.

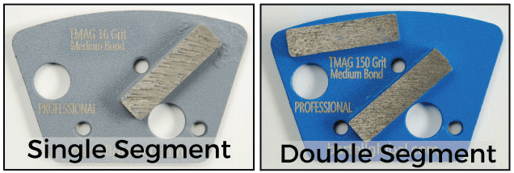

SINGLE SEGMENT VS. DOUBLE SEGMENT

Generally, Double Segments are the “Go To” option for most jobs. Single segment is used when you’re wanting more direct pressure, whether that is because you have a light grinder and need more direct downward pressure or because the coating you’re trying to remove requires more direct down pressure to remove it.

You can get double or single in rectangular or round segments. Both work well, but it’s mostly just user preference

GRINDING

PCD SERIES

PCD (Polycrystalline Diamond) tooling is a more aggressive option that will provide the power needed to get through and remove the toughest coatings, such as paint, varnish, glue, epoxy, acrylic, scree residue, VCT mastic, black tar adhesive, water proofing, parking deck membrane as well as thick rubbery material.

This can be use as the first step, in difficult coating removal- followed by each Girt series for an even smooth finish.

Shred Cut: Offers a long lifespan without sacrificing power and performance. This will cut think or thin coating quickly and effectively.

Shred Cut Light and Ultra-Light: Allows light weight machines to be more aggressive with tough coatings.

TCD: Offers a mix of PCDs and Metal Bonds. It’s fast and efficient for heavy duty removal of humps, mastics, thin-set, self-leveling compounds, and various light coatings on soft concrete floors. They also do well on metal shake floor.

GRIT PROFILES

Grit Profiles are what cause the varying scratch patterns in the concrete. The lower the Grit the deeper the scratches.

We have 4 Grit Profiles, 16, 40, 80, and 150, that are used in sequence to help achieve the appropriate finish.

16 Grit: This is the most aggressive Grit we have other than the PCD Series. Our Product Experts suggest this Grit for removing coatings like epoxy, thin set mortar or glue. If the concrete you’re finishing doesn’t have any coating or glue, or has a very fine layer of it, you’ll want to avoid using 16 Grit because it causes deep to medium scratch patterns that can be difficult to get out if unneeded.

40 Grit: Creates an average scratch pattern. Is usually used as the primary step for rough concrete floor, thin coating removal or to expose aggregate.

80 Grit: Creates a reasonable scratch pattern. Preliminary step when grinding new concrete.

150 Grit: Very subtle scratch pattern. Used to remove final remaining scratches and prepare surface for polishing.

Each grit is used in sequence to remove the scratch patterns from previous Grit until the surface is smooth and free of scratches. Not all steps are always necessary but the more steps followed the smoother the surface potential, which will result in a better polished finished.

POLISHING

RESIN SERIES

When it is time to switch from metal bonds to resins you have to start with what is called Transitional (or Hybrid) resin tooling. This will help to ensure the transition from grinding and smoothing with the metal bonds, to polishing with the resins, is flawless. We have 50 grit and 100 grit transitional (hybrid) resins available.

Similarly, to Metal Bond tooling, you can build your shine by using increasing Grit resins for each polishing step.

To help, Bartell Global has created an step by step Polishing System called iSHINE Floor System that will help you to achieve a flawless polished concrete finish if followed correctly.

As part of that, we have three series of Resin Tooling that you can choose from to help you achieve the finish you are looking for.

Resin Series 1 – 3” Pucks: These pucks have beveled edges for seamless passes. They are available in 50 (including Transitional/Hybrid),

100, 200, 400, 800, 1500, and 3000 Grit with an approximate lifespan of 5000 square feet. They are versatile and a cost effective option for most concrete floors, that will get you that perfect polish, you’re looking for.

iSHINE Resin Series 2 - Flex Pads: These pads are available in 9” and 11” and are a perfect option for old uneven concrete that can be

difficult to polish evenly. They have the ability to flex and reach into low points in the concrete, often referred to as “bird baths” because water can pool in those low spots, resembling a bird bath. They’re available in 30, 50, 100, 200, 400, 800, 1500, and 3000 Grit.

iSHINE Resin Series 3 – RD Discs: These resin discs are available in 7.5”, 9”, and 11” and are engineered to endure the high temperatures

that are a result of high speed polishing. The ability to endure these high temperatures allows for the user to achieve a very high gloss rating, and have an average lifespan of 10,000 square feet.

Each series can be used to step up the shine quality and gloss rating. It really all depends on what you’re trying to achieve.

Tooling is simply one aspect of Polishing concrete floors but if you don’t fully understand what the tooling is and how it works, you could end up struggling to achieve the polish you’re looking for, or even worse, you could damage your floor.

If you have any other question about tooling feel free to reach out and our product experts would be happy to help you with anything you need.

By

By