Why are we doing Screed Education Month? After the success of our Shotblasting Education Month in April, we’ve decided to continue the series and teach about another one of our signature products, our vibratory screed line. With many years of experience in manufacturing and using screed, we want to challenge misconceptions about screeding, provide practical education, and show you how effective screeding can take your business to the next level.

Laser Screed technology produces slab-on-grade concrete floors that are flatter and stronger than any comparative floors produced by using conventional methods. They establish grade by laser, utilizing a 3D Profiler System, disperse concrete by auger, and then vibrate and consolidate the concrete. The console mounted computer maintains grade with laser precision and monitors the screed elevation at a rate of 5 times per second.

Laser Screeds feature a self-leveling screed head that is mounted on a telescopic boom. Laser Screeds are setting new standards for concrete floors. In addition to being laser precise and mechanically powerful, they are fast. The average Laser screed can accurately screed 240 square feet of concrete in just 60 seconds. That means more floor is placed daily and production schedules are satisfied or actually shortened. Concrete mixes containing steel fibers can also be screeded with ease.

The real negative associated with laser screeds is initial cost. You will find that top of the line units range from $100,000 to $350,000 when purchased new.

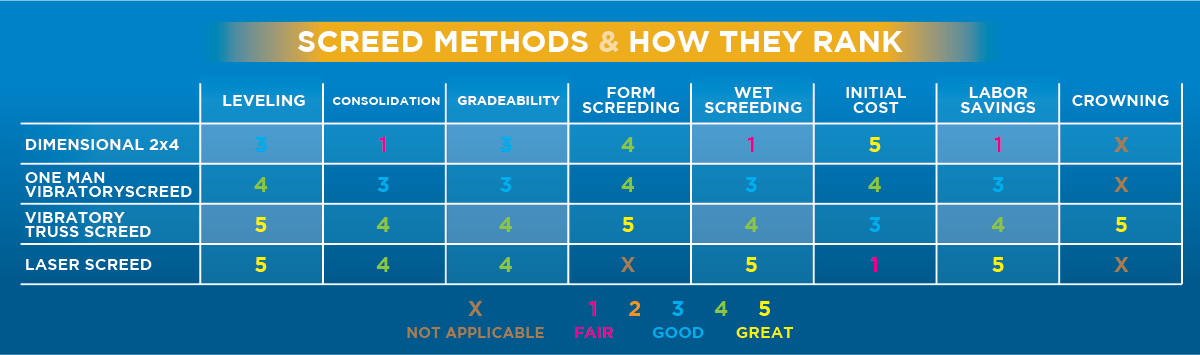

Clearly, laser screed is regarded as the best option in screeding. But is that really the case? Without question, laser precision and high production rates are unchallenged, but the initial cost point makes it an unobtainable option for most contractors. Does that mean a 2x4 is the only answer for everyone else? Not at all. As we've demonstrated over the month, there are options for each price point and contractor business that can help create a better end product and happier customer. One-Man Vibratory Screeds are great for the diverse contractor who only has the occasional pour. A Truss Screed, on the other hand, are for the contractor who needs a quality product he can trust for large pours (up to 80' wide). And of course, if pouring concrete is your full time job, Laser Screeds might be the choice for you.

We've worked hard to challenge some misconceptions about screeding machinery and why it really is more important than general perception would say. Hopefully we've helped clear up some of the confusion surrounding the practice and can help move you closer to making the right move for your business. But if you've still got questions or want to get more in-depth than we have here, the Bartell team have years of experience and would love to help you out. Contact us and we'd love to talk.

By

By