For years, within the concrete floor polishing industry, we were happy to grind and polish our concrete floors with planetary grinders, because, quite frankly, this was our only option. There were no other ways to do it! And, Planetary grinders are exceptional machines when it comes to preparing, profiling, and polishing concrete floors.

But, the challenge has always been this... Concrete grinding and polishing is a slow process and depending on the size of a project, it could be a lengthy, expensive and involved process to complete.

But now... "the word is out"... there are new systems in town that are making some pretty wild production rate claims. Claims that overshadow the traditional planetary grinder method. And what system is that?

It is the...

Power Trowel method of polishing concrete

Most contractors are aware of what a planetary grinder is: it is a large grinder fitted with diamond cutting segments with one LARGE plate rotating in one direction, which holds smaller grinder heads turning in opposite directions, resulting in very effective concrete cutting and polishing.

Most contractors are aware of what a planetary grinder is: it is a large grinder fitted with diamond cutting segments with one LARGE plate rotating in one direction, which holds smaller grinder heads turning in opposite directions, resulting in very effective concrete cutting and polishing.

And most flooring contractors probably at least know what a power trowel is: it's a machine with large 'fan-like' blades that is used to trowel wet concrete. Power trowels are used on freshly poured concrete in order to free trapped water in the slab and bring the cream to the surface of the slab. Power troweling also flattens the surface and consolidates the aggregate resulting in a beautifully finished slab. Power Troweling machines can come in two different styles: Walk-Behind or Ride-on.

Now, here's the cool part... engineers have figured out a way to leverage the large footprint of the Power Trowel to actually POLISH concrete at impressive rates.

How? By fitting these machines with devices that allow them to accept diamond polishing tooling.

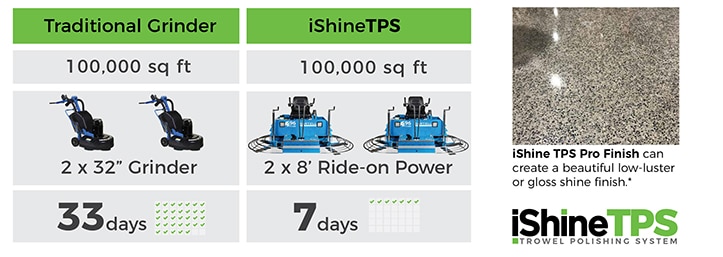

What is so attractive about the Power Trowel System compared to traditional planetary grinders? The answer is obvious in the chart below!

These stats are hard to believe... WOW! 100,000 sq. ft. in 7 days with 2 machines? Compared to 33 days with two large-format planetary grinders? If this is true - then as a seasoned polisher I can tell you that this would be incredible! Not to mention that this would change the industry!

Well... Is it true? The answer is Yes!!!

Recently, we were in Toronto, Canada to polish a 35,000 sq. ft. warehouse, which we completed in a little over 3 days! And the interesting thing about this polishing project is that we polished this area with inexperienced Ride-On Trowel operators! Yep, that's correct... machine operators that have never run a ride-on power trowel before and on their first attempt polished 35,000 sq. ft. in 3 days and that's with all the stops necessary when training on a new system! It was impressive, to say the least!

Here’s the problem though, if we just took ONLY these numbers into consideration we would probably sell our planetary grinders and buy a couple of ride-on power trowels. But!!! (and this is really important)... that might not be the best choice. If we stopped the conversation at only comparing production rates, we would be lacking a fair and reasonable comparison of the two methods.

What is true is this — as in most comparisons — there are pros and cons to each approach. So, let’s examine both systems, the Pros and the Cons, and see if one system is truly better than another.

Oh, to heck with it.... I think I might as well give you the end of this story right now... the truth is....

BOTH SYSTEMS ARE GREAT!

The reality is, there is a place for both systems! So, It is really important for contractors to understand when and where each system is used most effectively. This will allow a contractor to leverage the best system for their particular project and help them better maximize their profitability. Not to mention they can expand their range of services offered to their customer (by offering both options) and thereby increase the value of their business.

PLANETARY GRINDERS

There is a wide variety of Planetary grinders on the market today and a handful of brands have been around for many years now with great track records like my favorite planetary grinder, the Innovatech Predator shown in the picture above.

PLANETARY GRINDER ADVANTAGES

- Size options. Planetary grinders come in many size configurations (most commonly 18” – 32” machines). Smaller grinder machines give you access to confined locations and are easier to move around. Larger machines allow you to do larger areas faster.,

- Variable Speeds. Many machines have variable speed options. Lower speeds for removal of coatings and toppings and higher speeds for polishing

- Power options. Many planetary grinders come in a variety of power options - from 110 V – 230 V - 480 V and even propane options available so you can match your equipment to the needs of the job site

- No exhaust fumes. Electric models make working indoors a non-issue because they don't emit dangerous fumes when operating.

- Dual operation capabilities. Most planetary grinders can operate on a wet or dry surface so you have the choice of how you want to work.

- Highly versatile. Planetary grinders have a wide variety of tooling options available to them. These great options allow the machine to be used for a variety of tasks - like grinding off mortar, grinding epoxies, removing parking deck membranes, removing thin-set, or surface profiling and exposing aggregate. Of course there are also tooling options that allow you to polishing the concrete floor to a mirror finish.

- Easy waste clean-up. Planetary grinders that grind dry (and are coupled with a HEPA dust collector unit) can collect dry grindings in a bag format and can be disposed of easily (and safely) into standard wastes containers.

PLANETARY GRINDER DISADVANTAGES

- Slow going. Planetary grinding is generally a slow process, you are shaving fine layers of material at a time over a large area, and depending on how much material is to be removed, it just takes time.

- Equipment is costly. Like any type of specialized equipment, good machines aren’t cheap! On average, a grinder's costs are more expensive than ride-on power trowels. Yes... there are inexpensive planetary grinders out there — but a word to the wise... be careful when purchasing the cheapest grinder option. Cheaper models may look identical to the other machines, but may not be designed for longevity, or ease of fixing. Don't kid yourself, because these machines can do so much, they often "take a beating" when on the job site. So you want a machine that is tried and tested. And not to mention, one that is made with quality parts and is easy to repair on the job site (should you need to). The last thing you want from your grinder purchase is poor performance or frequent breakdowns.

- Additional equipment is required. If you choose to grind dry (as most contractors do) then you will need additional equipment. Grinding dry will require a HEPA Dust Collector system coupled with your grinder. It keeps the airborne dust out of the work environment and keeps you and your workers safe from health issues caused by silica dust.

- Higher Sq. Ft. Cost. Cost per square foot is often higher due to the time investment required to polish, making it too expensive and time-consuming for very large areas (ie: projects in the thousands of sq. ft.)

- More manpower is required. More manpower is often required for large projects which results in higher labor costs.

Now let's look at the alternative...

POWER TROWELS

Power Trowel Polishing. Power Trowel machines have been around for a really long time. In 1946 a self-taught immigrant machinist by the name of Arturo Bertolucci (Now, Art Bartell), designed and built his first power trowel. A machine that was used to speed up the process of finishing concrete - especially large areas of concrete. Now over 75 years later power trowels are still THE primary tool for finishing concrete. And thanks to engineering innovation, these machines can now be used for polishing floors! But like the traditional planetary grinder, there are pros and cons to using these machines for polishing...

POWER TROWEL ADVANTAGES

- High production Rates. Ride-on power trowels, with their much larger "footprint", cut a much wider swath per pass. And, coupled with the increased number of diamond segments you are able to mount to the trowel, these diamonds all cutting the floor at the same time allow you to cover a much larger area. And, cut that area faster, resulting in a significantly higher production rate compared to a traditional planetary grinder.

- Lower entry-level cost. Power trowels, especially walk-behind machines are considerably less expensive than planetary grinders, lowering the entry cost. And, a contractor already in the concrete or flooring trade may already own a power trowel. If they do, they need only to buy the tooling to begin polishing floors.

- Reduced labor costs. When you are able to complete projects 3-5 times faster with a power trowel? your labor costs go down sharply, consider the production rate comparison we looked at earlier, two grinders 33 days to grind and polish 100,000 sq. ft. of warehouse floor compared to two ride-on power trowels 7 days! So, instead of paying your crew for 33 days of labor, you are only paying for 7! That's a real reduction in labor costs.

- Profitable for large projects. Power trowels make large jobs with many thousands of square feet financially possible. Why? Because you're able to "get in and get out" so quickly that the cost to the end-user is less than the traditional grinding & polishing with a planetary grinder but still allows for a great profit margin for the polishing contractor. this benefits both the contractor and end-user.

- Quick turn-around times. This is really important, fast turn-around times are critical to end-users! Think about this, end-users have a company to run, they need you finished and gone! They need their floors back! ASAP! And the really fast turnaround time that you get with a power trowel is going to make you look great to both the end-user and the general contractor as well.

- Less additional equipment. When polishing with a power trowel you always cut and polish the floor "wet". this means, you flood the floor with water and work on the wet floor. Because you are working wet, you do not need expensive Hepa Filter dust extraction equipment saving that expense. On small to moderate-sized jobs, a wet-vac and a squeegee work ok. But, on larger jobs, it is far better to have an auto-scrubber to pick up the "slurry" created by the polishing process. The exception to "needing less equipment" is on big jobs. Jobs like the 100,000 sq. ft. job mentioned earlier. You really should have a good sized ride-on autoscrubber to keep up with the power trowel and work efficiently.

- Expanded service offering. Power trowels broaden the spectrum of services a contractor can offer. With the production rate possible with a power trowel you can pursue bigger projects than a contractor can do efficiently with one or two planetary grinders. Projects like warehouses, box stores, and manufacturing facilities become targets for bids.

- Reduced tooling costs. Generally, tooling lasts longer when grinding and polishing wet, with tooling specifically designed for power trowel application, the lifespan of the diamonds is really long. Consider this, if the average life of a 3" resin-bond puck is 6.000 - 8,000 sq. ft. and the average life of a "TPS" trowel polishing diamond is 30,000sq. ft.! We easily can see the cost savings in the life of the diamond.

- Easy on the Operator. Lastly, ride-on power trowels are a pleasure to operate! Where planetary grinders are mostly walk-behind machines, and we can be a little candid here, on big projects, it gets a little monotonous - power troweling is often done with ride-on units, they are just fun to operate. So who wouldn't rather sit to operate their machine all day versus stand on their feet? Disclaimer - Keep in mind... there are large ride-on grinders available too - but they are not often purchased or used due to their higher cost and investment.

POWER TROWEL DISADVANTAGES

- Slurry. Grinding wet creates slurry, a toxic watery mud that must be disposed of in a safe, legal method. Because concrete slurry is considered hazardous waste you must comply with local government guidelines to dispose of it correctly. Which, to be fair, in most cases is not a really big deal, you just want to make sure you do it correctly.

- Limited Visibility. Power Troweling "wet" makes it difficult to see your scratch pattern. Polishing in its most basic sense is similar to sanding wood - your start with your coarse grit and progressively work up to your finer grits so that you have a smooth finished product. Concrete polishing is the same principle - you start coarse and progressively use finer grits. Each grit level is focused on removing the scratches of the grit before it. So when grinding it is pretty important to continuously check for an even scratch pattern. When power troweling it is good to have a second person checking your progress intermittently to let you know how you are doing.

- Limited Access. Ride-on power trowels are big machines, and they often don't fit into small places or through most doorways. So large bay-door access is usually required. Big trowels can also be a challenge to mobilize. These realities mean that you will be limited in the type of projects you can access with a power trowel. (UPDATE!!! Check out our brand new BXR830 Ride-On Trowel, which we designed specifically for the TPS system, AND at only 30" wide will fit through a standard doorway)

- Messy process. Polishing with a power trowel can be a little messy because it MUST be done wet (there are no dual options like there are with planetary grinding). Some projects with high-end finishes on the walls or adjacent floors or, a sensitive environment make this method less desirable - and in some cases unacceptable due to the splashing of slurry and the wet floor requirement.

- Proper ventilation required! A power trowel is usually equipped with gasoline or propane engines - which of course emit exhaust fumes. Exhaust fumes in the open are not a problem, but in small, enclosed environments - proper ventilation is required. And in some cases (like working in an occupied building or medical facilities) you would be banned from using this type of equipment. In these special cases, a planetary grinder would be your only option.

- No exposed aggregate! Ride on-trowels do NOT have the downward pressure needed to aggressively cut the floor in order to expose aggerate or even produce a "salt & pepper" finish (small flecks of stone exposed). Which is typically only achieved with planetary grinders. So if you are using the power trowel method and want exposed aggregate - you must first cut the floor with coarse diamond grit using a planetary grinder. Which of course just adds complexity and cost to your process.

CONCLUSION

There is definitely a place for both methods - but because of their limitations - power trowels will never replace the traditional planetary grinder. Likewise - because of the incredible production rates of power trowels - planetary grinders will have trouble competing on the 30,000 to 100,000 sq.ft. projects (depending on the desired finish, that is).

So if I was asked to recommend what system a contractor should invest in I would say this:

For the smaller contractor (doing projects under 10,000 sq.ft.) it would make sense to purchase a planetary grinder. BUT if that same contractor wanted to focus on doing large-scale projects - then they would seriously consider purchasing a power trowel system. Essentially purchase one type of machine that best fits the size and type of projects you will actively pursue.

But for larger contractors - it might make more sense to invest in both types of machines - so that they can increase their capabilities and future opportunities, and be able to service both large, medium, and small scale projects.

Are you interested in focusing on large format projects? If so, check out this video on the iShine Trowel Polishing System (TPS), it's pretty cool!

INTRODUCTION TO POWER TROWEL POLISHING

Or if you want to learn more about the traditional planetary grinder/polisher approach - check out the video we created on planetary grinder tooling for polishing.

By

By