How to Identify What Equipment Was Used to Profile a Concrete Floor along with some pros and cons for each method.

Concrete floors are often prepared or "profiled" using specialized equipment to achieve specific surface textures and finishes. If you're new to the world of concrete construction or maintenance and repair, understanding how to identify what equipment was used to profile a concrete floor is a necessary skill to develop.

The reason? because depending on what the desired finish on the floor is to be, some methods are much more appropriate than others. In this guide, we'll walk you through the key steps and tips to help you recognize the telltale signs of different profiling methods.

FIRST...

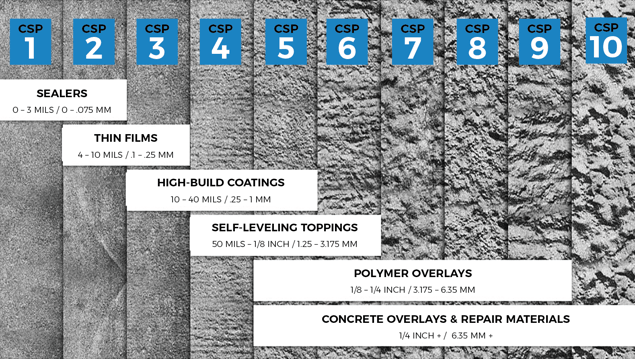

Understanding Concrete Floor Profiling: Before we dive into the specifics, let's briefly review what concrete floor profiling entails. Profiling refers to the process of preparing a concrete surface to enhance adhesion for coatings, overlays, moisture mitigation systems, or repairs. It involves creating a textured surface by removing a thin layer of concrete or altering its surface characteristics. The degree of profiling or the roughness of the surface is referred to in the industry as “CSP” or "Concrete Surface Profile" and has a range from “1”, being a very smooth surface to "10" being a very rough surface as we see below...

CSP chart

There are basically 4 commonly used methods and equipment to accomplish the task of profiling concrete to the correct, "CSP", they are…

- Diamond grinding.

- Shot-Blasting.

- Scarifying

- Diamond drum Shaving.

CLICK HERE FOR MORE INFORMATION ON SURF-PREP EQUIPMENT

Let’s identify the tell-tale signs of each method one at a time, First…

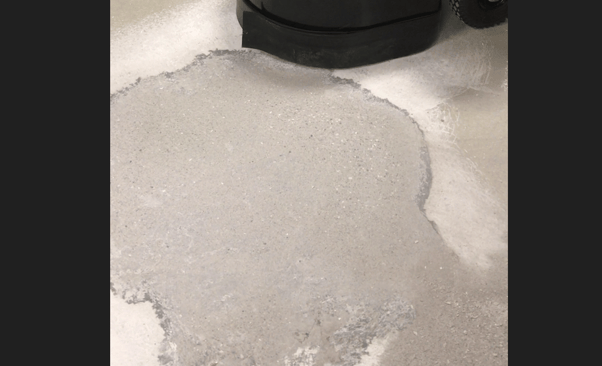

Diamond Ground surface

Couple examples of a Diamond ground surface

typical diamond segment.

Identifying Diamond Grinding: Diamond grinding is a common method where multiple diamond segments like the one shown above are attached to the base of a diamond grinder like the three headed planetary grinder shown here

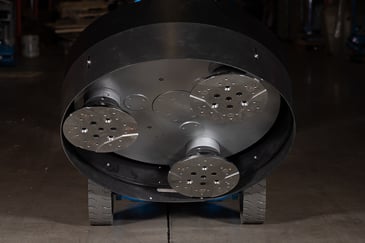

Cutter heads of a Planetary Grinder

Cutter heads of a Planetary Grinder

Each of the three heads shown will take three diamonds each, totaling nine segments and is used to achieve a smooth and flat surface that can, depending on the concrete and the grit of diamond segment use, can result in a CSP of 2-3 typically. Look for the following signs to identify if diamond grinding was used:

- Smooth, monolithic, polished appearance: Diamond grinding typically leaves a smooth, consistent surface and with finer grit diamonds a progressively more refined, polished finish on the concrete surface.

- Fine dust residue: The presence of fine dust particles (A downside to grinding) imbedded in and around the surface area is a common indicator of diamond grinding and must be removed before applying a finish to the floor.

- Uniform surface texture: The surface should exhibit a consistent texture with minimal visible irregularities or rough patches.

Pros and Cons... - 👍Flatter floors: diamond grinding removes a lot of the subtle high spots that all concrete surfaces have.

- 👍Floor covering contractors: that install carpet, VCT, SV, rubber flooring, LVP love to install over a diamond ground concrete surface, it produces a suburb "Blank canvas" to begin their work.

- 👎Coatings applicators: mostly shy away from diamond grinding because of the need to be very thorough at removing the dust (A bond breaker) that typically becomes imbedded in the surface and must be removed. Also, water is often used in the grinding process to eliminate dust in the air and is a real potential problem for coatings applicators as moisture can lead to failures when applying epoxy coatings.

- 👎Slow process: Typically, Diamond grinding is the slowest way to profile a concrete surface.

Shot-Blasted surfaces

Recognizing a Shot Blasted floor: Shot blasting is another popular method used for concrete floor profiling.

Shot media. (2 sizes shown)

Shot media. (2 sizes shown)

A Shot-Blaster is a machine that shoots small steel beads known as "Media" onto the floor at high speed and breaks away the surface of the concrete producing a wide range of CSP depending on the size of the shot used, the speed of the machine moving forward, and the amount of shot introduced to the process. Here's how to spot signs of shot blasting:

- Rough, textured surface: Shot blasting creates a rough, textured surface with small indentations and irregularities.

- Blast patterns: Look for angular patterns or "Shot-Blast tracks, often referred to as "Corn-rows" on the surface, which are characteristic of shot blasting. (See the image above)

- Clean surface: Shot blasting leave behind a very clean surface although at times small debris or abrasive media can be embedded in imperfections in the concrete surface. It is also necessary to go over the floor with a "Magnet sweep" to pick up the stray shot that inevitably is left behind.

Pros and Cons...

- 👍Shot blasting leaves that super clean surface with NO dust imbedded into the concrete surface.

- 👍Shot blasting is much faster than diamond grinding or any other form of surface profiling.

- 👎Shot blasting leaves (Depending on the machine and skill of the operator) corn-rows that can be seen and sometimes are bad enough to "Telegraph" through thin materials and thin epoxy applications negatively impacting the appearance of the coating applied.

- 👎Depending on the CSP, you will use a lot more material like epoxy, to coat a floor upping your cost per square foot compared to a diamond ground surface.

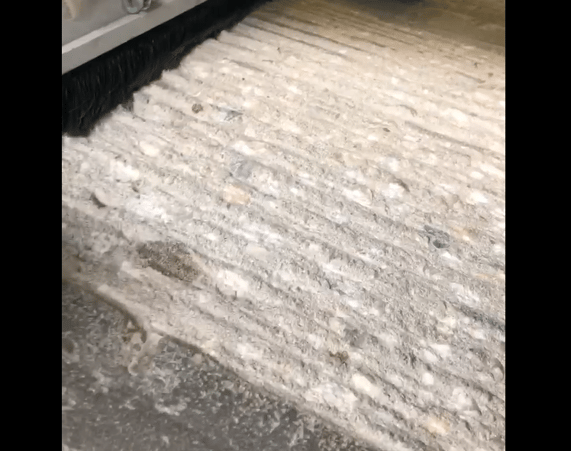

Scarified Surface

Identifying Scarified surfaces; Scarifying involves using a machine with rotating cutters attached to a drum that "Flail" against the concrete and breaks away the surface material,

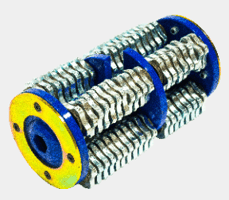

Scarifying drum

Scarifying drum

this creates a rough textured surface with a Typically high CSP. Here are the signs to look for:

- Rough, uneven surface: Scarifying produces a rough, uneven surface with visible grooves or lines.

- Deep gouges or channels: The concrete surface may exhibit deep gouges or channels, especially in areas where the scarifying machine has been more aggressive.

- Coarse debris: Scarifying can generate coarse debris, such as larger concrete chips or fragments, which may be visible on the surface and not removed by the attached Hepa vac system and must be removed with additional passes with a Hepa filter vacuum.

pros and cons...

- 👍Scarifying is fast: this process removes a lot of material quickly. so, if your needing to bring the surface of the concrete down a lot, Scarifying is a great option.

- 👍High CSP: if you are needing a verry rough surface with a high CSP rating, Scarifying is probably your best option.

- 👍Safety concerns: Scarifying is great for quickly removing tripping hazards like Frost heaves and tree root lifted sidewalks.

- 👎Concrete surface damage: Flooring and coatings contractors mostly hate working on a Scarified concrete surface because so much damage is done to the surface that calls for a great deal of additional patching and "Floating" the floor to get it to an acceptable condition for a successful recoat or flooring install.

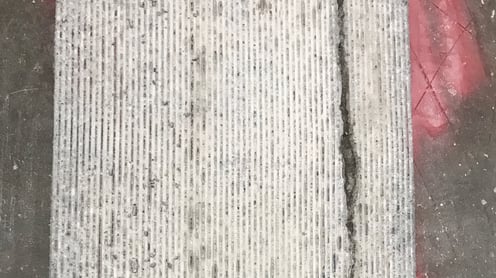

Shaved concrete surface

Recognizing a shaved Concrete surface: Concrete shaving, also known as concrete milling, incorporates a diamond blade drum with up to 70 diamond blades like the drum shown here...

Shaving drum.

Shaving drum.Shavers are used to remove layers of concrete to achieve a specific depth or surface finish. unlike the Scarifiers, shavers do NOT impact the concrete surface. They, as the name suggests, "Cut or shave" the surface of the concrete off with diamond blades. Here's how to identify it:

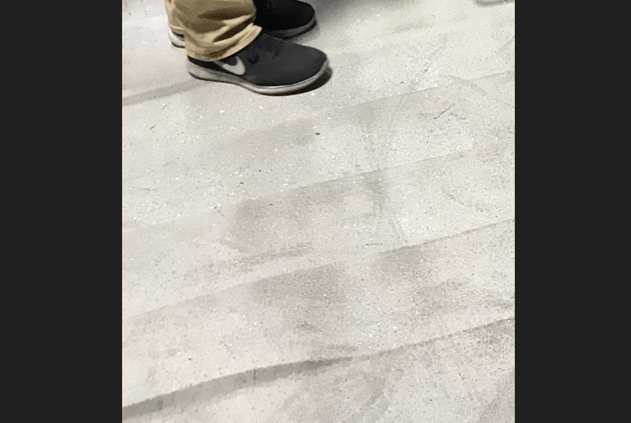

- Flat surface: Concrete shaving creates a consistent, flat surface with some but minimal "corduroy" like texture. (See above image)

- Shallow cuts: Unlike scarifying, which creates deeper grooves, concrete shaving while it's possible to cut deeply in one pass, typically contractors apply multiple, shallower cuts and are more uniform in depth.

- Clean, uniform appearance: The surface should have a clean, mostly uniform appearance with minimal visible roughness or irregularities. (With practice)

- Shaving marks: or "Corn rows" are readily apparent.

Pros and cons?...

- 👍a great concrete shaver is an incredible time saver, it removes the concrete surface quickly and deep.

- 👍Verry consistent, repeatable surface.

- 👍Can easily be "Fine tuned" to just skim the surface and only remove "High spots" in a concrete slab.

- 👍Some machines like Bartell Global's CT320 Shaver can actually switch from a shaver drum to a scarifying drum giving a contractor the option to choose two methods of profiling using just one machine.

CLICK HERE FOR INFO ON THE CT320 ONE OF MY FAVORITE MACHINES - 👎There is a learning curve to operating a concrete shaver. you must be trained to successfully operate a concrete shaver.

- 👎Challenge to mobilize: These are serious surface preparation machines and hard to stage along with high power requirements and must be operated with a big, capable, hepa filter dust extraction system.

a shaved concrete surface and a scarified surface share some identifying characteristics and the two profiles can be confused, here is a comparison of the two...

Shaved surface, small defined grooves.

Scarified surface, wide sloping groves.

A Critically Important Related Point...

Anytime you are removing concrete it is imperative that you use the correct dust extraction system for the machine being used to profile concrete...

- 👍Always use the correct, OSHA approved, HEPA filter system that removes 99.97% of all harmful Silica laned concrete dust from the air.

- 👎NEVER use a Shop-Vac, they clog verry quickly, they do not remove the Silica dust from the air, it is harmful to you and your employees and bystanders, and if that is not enough... OSHA (IN the USA) starts their fines at $10,000 if you get caught!

Conclusion By familiarizing yourself with these key characteristics of concrete profiling, you'll be better equipped to identify what equipment was used to profile a concrete floor. Remember that each profiling method leaves its own distinct imprint on the concrete surface, so careful observation and a keen eye for detail are essential. If you're unsure or need professional assistance, don't hesitate to consult with experienced concrete contractors or specialists. also, call us here at Bartell Global and we can help with identifying what profiling process was used.

We hope this guide has been helpful in demystifying the world of concrete floor profiling. With practice and attention to detail, you'll soon become adept at recognizing the unique signs of different profiling methods!

we at Bartell Global manufacture a wide variety of all the equipment covered in this article. click the link below to receive more information on surface preparation equipment.

By

By