All concrete is HARD if you fall and hit the back of your head on it, whether it is 2,500 PSI in your home or 8,000 PSI on a bridge or military installation! But, In the construction world, where a lot of us live, it is often critical to know the properties of concrete so we can select the correct tooling. One of these important properties is HARDNESS. This is referred to as its PSI or compression strength measured in pounds per square inch. This information is critical in determining if it is acceptable for the project it is to be used on. Or, if you are cutting or grinding concrete you need to know the PSI so you can select the correct diamond matrix to be used.

CLICK HERE FOR HELP IN CHOOSING THE CORRECT DIAMOND.

Just a little FYI here, we in the USA use PSI when determining concrete hardness, it is an Imperial measurement, pounds per square inch. But most of the rest of the world uses a metric rating known as MPa or Megapascals (whatever the heck a Megapascal is, I looked it up and my eyes just kinda glazed over, something to do with a Newton being a measurement of force and pushing a gram of matter at a certain velocity, stuff like that….I’m sticking with PSI!)

Here is a general comparison between the two ways of measuring concrete hardness as well as what is considered hard and soft concrete.

| 2500 psi | 18 MPa | soft |

| 3000 psi | 20 MPa | med-soft |

| 3500 psi | 25 MPa | medium |

| 4000 psi | 30 MPa | medium |

| 5000 psi | 35 MPa | medium-hard |

| 6000 psi | 40 MPa | hard |

This comparison is not exact but if you need exact comparison use 0.00698915 to convert PSI to MPa

CONCRETE, THE FACTORS INVOLVED

So then, what is it that makes concrete hard or soft? Well, there are a number of things affecting concrete hardness.

AGGREGATE – the rocks in concrete

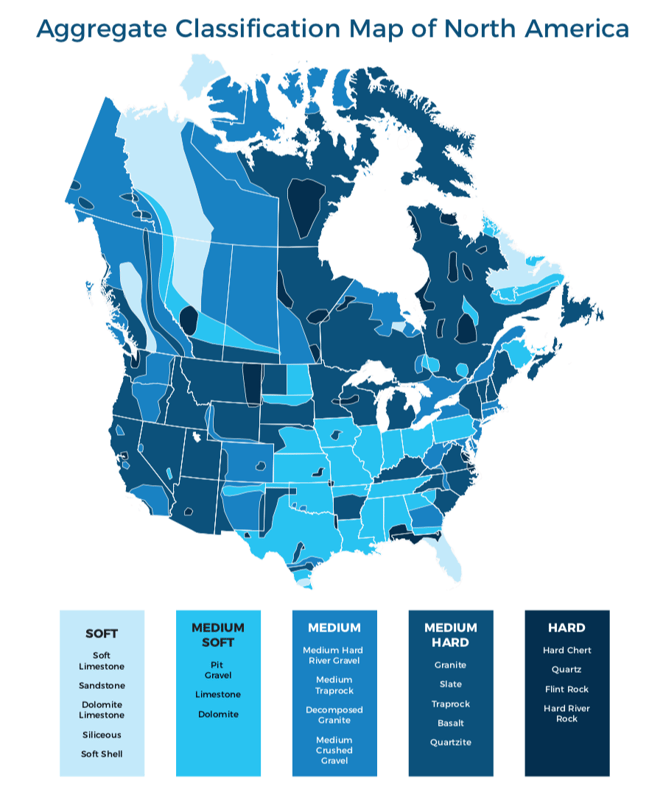

This material accounts for about 70% of a concrete mixture. So, it is very important and varies greatly across the country. Where the aggregate is made up of very hard rock like granite, chert, quartzite you tend to get harder concrete. In places with aggregate made of shale, sandstone, and limestone you, get softer concrete. The following map gives a general idea of hardness and softness across the country as influenced by aggregate composition, but as we will see there are other factors that determine the hardness of concrete as well.

MIX DESIGN - you don’t just “add water” after all!

Concrete mix design is the process of developing the correct proportions of cement, water, and a range of aggregate from sand to larger stone, (usually up to 1.5" diameter) to achieve the desired hardness for both performance and durability. There is also a wide range of both chemical and mineral additives available. Their purpose will depend on what the contractor wants to achieve, weather shrinkage reducers to accelerating agents helping in the curing process and a host of others. Often included in the concoction are materials like FLY ASH, which was originally used as a filler in concrete to reduce stores of the coal power industry by-product. Millions of pounds of it were once deposited in landfills every year until it was found that it increases the hardness of concrete.

THE CURING PROCESS

Growing up I just assumed, like probably everyone else, that concrete cured by drying and we were all totally wrong. Concrete cures by a chemical process called “hydration” where the components in cement form a chemical bond with water molecules and become hydrates, thus the name.

It is important then to not let the concrete “dry” before the hydration process has taken place as this makes for a weaker slab that's more prone to cracking. In fact, as the concrete hardens it is sometimes necessary to spray the surface with water, keeping it wet to allow the necessary time for hydration to take place. In fact, concrete will harden just as well—if not better—underwater if you can keep from “washing out” the concrete mix.

As a personal example, I once mortared rock onto a wall in the direct summer sunlight. The next day I came out to observe my quality installation and found almost ALL the rock on the ground. After accusing my supply house of selling me defective mortar, the salesman patiently explained the importance of the hydration process to me. I had let the mortar dry way too fast!

OTHER THINGS THAT MAKE A DIFFERENCE

- A slab poured in cold, wet conditions will make for a harder slab

- The reverse is true when poured in hot, dry weather

- Power troweling can create a very hard surface even if the concrete is soft underneath

HOW DO I TELL IF I HAVE HARD OR SOFT CONCRETE?

There are two tools commonly used for testing the hardness of concrete. They are the rebound hammer and the Moh’s scratch test.

The rebound hammer has a spring loaded piston that is “fired” by the user onto the surface of the concrete, the amount of rebound gives a PSI rating for the slab. I like this one as it tells you about the whole slab and not just the very top surface.

The Mohs test is a more commonly used tool to test for hardness. The test has a rating from #1 to #10 but for testing concrete, you would look between #2 and #9 (considering #1 is the hardness of talc... And #10 is the hardness of diamond). The kit consists of 4 stylus tools with pointed tips at each end made of materials (plastic, copper, various alloys) with varying degrees of hardness, ranging from the #2 - #9 tip.

To test your concrete slab’s hardness, you would start with maybe a #9 and make a small scratch on the surface of the concrete, applying just a light amount of pressure, let the pick do the work... If the concrete shows a visible scratch, move down to #8 and so on until your pin-tip does NOT scratch the surface. For example, if it scratches with #7 but not #6, this is your stopping point, 6.5 in hardness. You then look at the chart provided and that gives you your concrete hardness in PSI. This is a good tool and less costly than the rebound hammer (which can range up to $600.00 bucks, as opposed to the Mohs kit around $120.00 bucks). The only thing I don’t like about the Mohs kit is that it tells you only about the very top surface of the slab, where the rebound hammer reacts to the entire depth of the slab.

TO SUM UP

So, you can get an idea of concrete hardness by looking at the aggregate used as well as the geographic location, but there is a lot more to making hard or soft concrete. I live in the Northwest, Washington state on the Puget Sound and we have some of the hardest concrete on the continent but I will find very soft concrete here at times and it is because of all the other factors that go into making hard-medium-soft concrete.

By

By