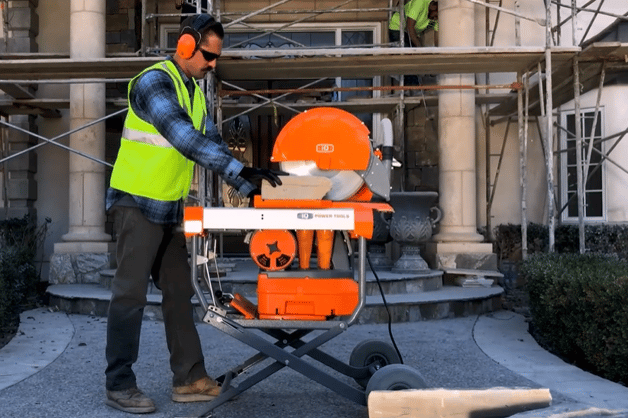

WET CUT SAW

If you are a Tile-Setter or you set blocks or install Pavers for a living, the unavoidable, unpleasant aspect of the job is making cuts… When it comes to tile, masonry, stone or hardscape paver cutting, traditional methods often involve saws like the one shown here, a messy wet saw, and if you didn't use a wet saw, the tile cutting would release harmful dust particles, causing discomfort and posing serious health risks. Wet saws has just been an unpleasant part of the industry. However, with technological advancements, this is no longer the case... Every contractor that has ever gone home wet and muddy after a day making cuts with a "Wet Saw" immediately askes the question... what technological advancements?

CUTTING TILES, PAVERS, BRICKS WITHOUT WATER AND DUST!!!

Dry cut saw

Dry cut saw

Yup, no dust, how is this possible? It is possible with the correct use of the latest dust extraction technology and here are 5 reasons why every contractor using a wet saw should consider "Dry Cutting"...

- Precision Cutting Without the Mess

Waterless and dustless tile saws offer the advantage of precision cutting without the need for constant water supply. Traditional wet saws utilize a water reservoir to remove dust and cool down the blade during cutting, which can result in water spills, messy work areas, wet and muddy contractors, inconvenient and time-wasting trips back and forth from the work site to the cutting site. As well as the risk of slipping on a wet floor. In contrast, waterless tile saws use advanced dust extraction systems along with diamond-coated blades to achieve precise cuts without the mess. This not only ensures a safer working environment but also reduces the time and effort spent on cleanup.

- Healthier Work Environment

Dust particles generated during tile cutting pose a significant health hazard to workers, as well as anyone in the vicinity. Prolonged exposure to tile’s dust that contains silica can lead to respiratory problems, allergies, and even more severe conditions like silicosis, a lung disease caused by inhaling silicate laden dust from cutting tiles, concrete, brick and other silica containing materials and is not curable.

Dustless tile saws incorporate efficient dust collection systems that capture and contain dust at the source, eliminating airborne particles. By using these saws, professionals and DIY enthusiasts can protect their health, making their workspace safer and more comfortable.

- Environmental Benefits

Waterless tile saws contribute to environmental conservation in two ways, first...

By reducing water wastage. Traditional wet tile saws consume water during the cutting process, leading to unnecessary water usage.

Also, with Wet Saws you have the need to properly dispose of the "muddy residue" left over from the traditional cutting process that uses water to cool the diamond blade and keep the dust out of the air, this "Muddy residue" is referred to as "Slurry" and is considered hazardous waist an must be disposed of according to local by-laws and codes.

With waterless tile saws, there is no need for water supply or the necessity to dispose of the slurry making them an eco-friendly option for individuals and businesses looking to reduce their environmental footprint.

CLICK HERE FOR MORE INFORMATION ON THE METHODS OF DISPOSING OF SLURRY CONTAINING SILICA

- Versatility and Mobility

Waterless and dustless tile saws are often more compact and portable compared to their traditional counterparts. Their lightweight design allows for easy transportation between job sites, making them ideal for professionals who frequently work on different projects. Additionally, these saws are suitable for indoor applications, as they eliminate the need for water containment, making them a versatile and convenient tool for all cutting needs.

- Cost Savings

While waterless and dustless tile saws may have a higher initial investment compared to conventional wet saws, they offer significant long-term cost savings. The improved efficiency saves time and labor costs. Moreover, the enhanced dust collection systems result in reduced clean-up expenses and maintenance costs, making them a cost-effective option in the long run.

The Conclusion…

Does dry cutting saws completely replace wet saws? Probably not, but, Waterless and dustless tile saws are truly revolutionizing the tile cutting industry, addressing environmental concerns, improving safety and health standards, and enhancing overall work efficiency.

These innovative tools are a prime example of how technology can be harnessed to create a positive impact on both the construction sector and the environment. As the demand for eco-friendly and user-friendly equipment grows, waterless and dustless tile saws are poised to become the go-to choice for professionals and DIY enthusiasts alike.

Embracing this cutting-edge technology not only benefits individual projects but also contributes to a greener and more sustainable future for the construction industry.

Who is leading the industry in dustless, waterless tile cutting?

For over 20 years IQ has been leading the industry in dustless, waterless cutting.

Because of the close business relationship Bartell Global has with IQ Power Equipment, I recently had the opportunity to tour their facility in Moreno Valley CA and I gotta tell you, I was impressed! Being a commercial flooring contractor for almost 40 years and having came home many times wet and muddy from working a wet saw, I was amassed at the variety and effectiveness on the saws when cutting tiles, pavers and various masonry materials.

I would just conclude with this... My contractor days are behind me, but if they weren't, and if they are not for you, I would definitely add a couple to my equipment arsenal and highly recommend that you consider IQ dustless and waterless saws for your next equipment purchase.

CLICK HERE FOR MORE INFO ON IQ POWER TOOLS

By

By