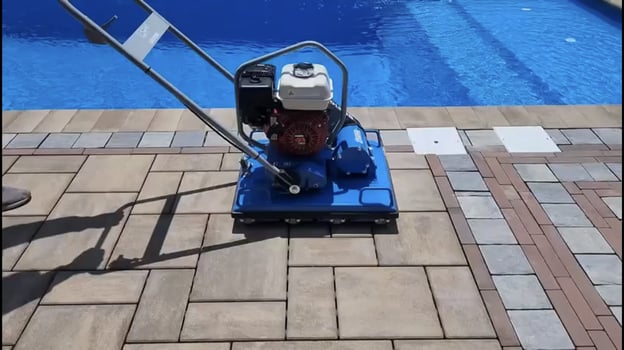

in the "Olden Days" we rode horses because there were no cars, used phone booths to make calls because cell phones did not exist, and contractors used Plate Compactors with pads, plywood, chunks of carpet, to consolidate joint materials in paver projects because they did not have a choice. We know what replaced horses and phone booths but what about compaction plates for consolidating joint materials? is there a new piece of equipment that replaces compaction plates? yes!

Paver Rollers… they are quickly changing the hardscape equipment world. In this Blog, we are going to explore the value of a paver roller to contractors.

If you are a contractor that installs pavers, stone, or porcelain materials for hardscape projects, there is a good chance that you already know the latest equipment sensation in the hardscape world is the Paver-Roller.

Why is that? Unlike compaction plates in general, a paver roller is a dedicated piece of equipment that is exclusively used in only one stage of the process, Paver Rollers “Consolidate” joint sands, crushed stone & dust, and materials like Polymeric Sands into the joints of paving materials like pavers, stone, porcelain and other materials to interlock the pavers. Contractors need to achieve this interlocked condition to complete their projects.

Importantly, Paver Rollers accomplishes this with very minimal or no damage to the surface of the material.

The features of a paver roller… the features that make them so different than traditional compaction plates and so valuable to a contractor are not many but verry important, they are…

- Polyurethane Rollers… instead of a steel compaction surface, Paver Rollers have 4-5 polyurethane rollers that protects the surface of the flooring materials.

- Rollers… rollers roll, you do not have to “Drag” the machine around like traditional compaction plates, scratching the surface of the finished material installed.

- Efficient exciters… Exciters that are designed to gently and effectively consolidate the joint materials right down to the bedding layer.

The benefits of a Paver Roller…

- Safe, non damaging consolidation… effective joint consolidation without the risk of cracking, chipping, or damaging materials which can happen with a traditional compactor.

- Time Saving… a paver roller covers a large area quickly, reducing the time spent on consolidation.

- Consistent compaction… the rollers apply uniform pressure, insuring consistent compaction across the entire surface.

- Reduced Labor Cost… by streamlining the consolidation process, contractors can save on labor costs, making projects more profitable.

In the competitive world of hardscaping and paver installations, contractors are constantly seeking ways to enhance efficiency and quality. A Paver Roller is a valuable tool that can make a significant difference in achieving these goals. By investing in a Paver Roller, contractors can streamline their operations, improve the quality of their work, and ultimately, enhance their reputation in the industry.

So, if you want one, there are just a few manufacturers out there making Paver Rollers, which one do you pick??? Well, as one of the product trainers for Bartell Global, I am probably a little biased, but we have taken the industry lead in engineering and manufacturing Paver Rollers and with our well over 75 years in the equipment manufacturing business, we are pretty good at it, we know what we are doing and we manufacture truly great equipment, one great piece of equipment is our Paver Roller, the BPR1080

With features like…

- Choice of a 5 or 4 roller configuration.

- Adjustable handle for operator comfort and safety.

- Rack & Pinion throttle for ease of use and safety.

- Powers by a highly dependable Honda GX160 engine.

- Loading and unloading is made easy with 4 lifting handles and a lift strap location.

- Protective “Bumper” around the outside of the machine that protects finished wall surfaces.

- Roller locking mechanism to prevent the machine from shifting during transport and storage on unlevel surfaces.

- Reversable handle that allows you to operate the machine from the front or back.

Features like these makes the BPR1080 an excellent choice for a Paver Roller.

For additional information contact your local distributer or contact us, Bartell Global, directly.

By

By