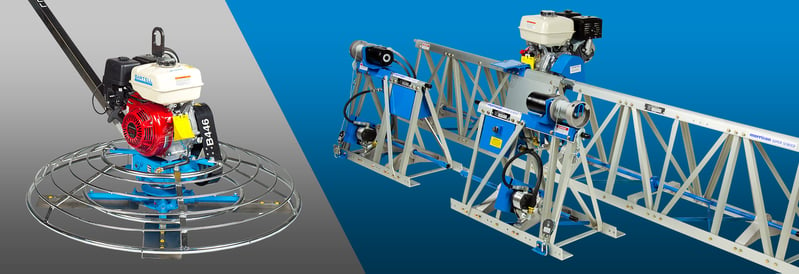

Using both a powered Truss Screed and a power trowel are a common sight on commercial concrete projects as well as road construction. Why? because on these types of projects, concrete must perform to it's greatest potential. To achieve that, a Truss Screed and Power Trowel are two pieces of equipment that are important when placing concrete that must perform at these highest levels.

They are not as commonly seen on residential concrete placement projects, especially Truss Screeds…

This raises a couple questions...

- What exactly does a Truss Screed and Power Trowel do to enable a concrete slab to perform to its greatest potential?

- Why are they primarily used in commercial settings and not as common on residential projects?

First, what do they accomplish?

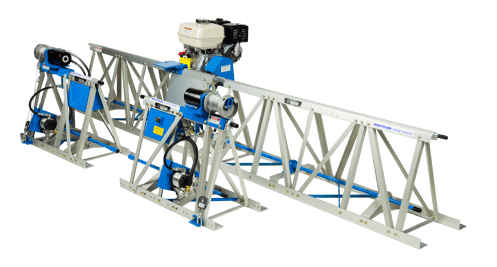

TRUSS SCREEDS…

A Truss screed is one of the first pieces of equipment used in the placing of concrete, when the concrete mix is at its lowest viscosity and at its easiest point to screed off. Contractors refer to this as “Striking off” the slab. Here is what is accomplished by using a powered, vibrating, Truss Screed…

A Truss screed is one of the first pieces of equipment used in the placing of concrete, when the concrete mix is at its lowest viscosity and at its easiest point to screed off. Contractors refer to this as “Striking off” the slab. Here is what is accomplished by using a powered, vibrating, Truss Screed…

- Ease of placement… Truss screeds make “Striking off” the wet concrete much easier

- Consolidation… Vibrating Truss Screeds effectively and quickly consolidate the concrete to a depth of over 12" (With some machines) locking the aggerate in place

- Air pocket removal… Truss Screeds remove air from the wet concrete, air pockets weaken the concrete and gives a place for water to collect. and in cold environments, these water filled and now frozen voids damage the concrete slab because water expands 9% when it freezes and exerts great stress on the concrete, making it susceptible to cracking, spalling, and deterioration, this is often referred to "Mechanical Weathering" and gets worse with each freeze - thaw cycle

- Adjustable surface results… Many Truss Screeds can be adjusted so that the concrete pour will either have a “Crown” like roadbeds have, or a consistent level surface like many commercial applications require, or even a “valley” in the slab sometimes needed for water direction and runoff

- More consistent finish… When using a Truss Screed, you can achieve a much higher FF (Floor flatness) reading as well as the ability to adjusting for FL (Floor level) if needed compared to other methods

- Higher PSI results… You can screed thicker concrete with a less than 2" “Slump”, resulting in a concrete slab with a much higher PSI reading

Clearly, when producing a high preforming, quality slab, a Truss Screed accomplishes a lot at the beginning of the pour So, after screeding comes power troweling. What is accomplished with a power trowel?

POWER TROWELS…

Power trowels are the next step in producing that high preforming quality concrete slab. They come in a variety of types and sizes, anywhere from a small 24” walk-behind edger to 10 ft. wide ride-on machines. With a power trowel you are taking two basic steps, you are “Floating” & “Finishing” the surface of the concrete slab. With these two steps, power trowels accomplish the following…

- Time saver… walk-behind power trowels save a lot of time and manpower, a ride-on trowel saves an even greater amount of time, allowing you to work much larger projects

- Fine leveling… an experienced operator can actually take down or fill in Subtle high and low spots

- Consolidation… Power Troweling continues the process of consolidating the surface of the slab

- Water removal… power troweling brings excess water (Laitance) to the surface

- Lessens the chance of cracking… Cracking and crazing occurs with all concrete but with a properly TIMED and TROWELED surface it is lessened. Quick warning...Troweling too early in the curing process, has the opposite effect. It can result in a much weakened slab surface. The timing of when to start power-troweling is critical to a successful outcome

- Surface Densification… power troweling produces a smooth, hard, dense surface. By progressively increasing the angle of the blades, the surface is forced to expel excess water and air. Continually compressing and sealing that top surface material producing a highly densified surface layer often referred to as a “Burnished surface”… NOTE…this is not to be confused with a chemically densified floor, as you would see done in the concrete polishing process. these densifier chemicals are applied to fully cured concrete surfaces

Understanding what Power Trowels and Truss Screeds accomplish makes it clear that they are a critical part in the placing of concrete that must perform to its highest possible potential.

Second question asked,... why are they not always used in residential projects?

- Truss Screeds... On most residential projects a Truss Screed is just not necessary, residential projects are typically smaller in size and the performance requirements of the concrete are not as rigorous as commercial applications making Truss Screeds not commonly used.

- Power Trowel... Though not always used in residential projects, power trowels, mostly smaller walk-behind machines, are still commonly used.

If you are interest in additional information on either power trowels or Truss Screeds, click the links below...

CLICK HERE FOR MORE INFORMATION ON TRUSS SCREEDS

CLICK HERE FOR MORE INFORMATION ON POWER TROWELS

By

By