If you are a concrete placement contractor looking to purchase a Truss Screed there are a lot of systems to choose from, some are good choices and some, not so good…

What are the features and benefits that make a great Truss Screed that a contractor should be looking for? There of course, differences in opinion. So, when researching information on any purchase, especially a pretty big purchase as a Powered Vibratory Truss Screed is, doing your research is critical. Also, consider a variety of opinions, from people like other contractors who have Truss Screeds to manufacturers and distributers... This article is my opinion of what makes a great Truss Screed,

What are the features to look for in a great Truss Screed?

- ALUMINUM CONSTRUCTION… there are FOUR reasons why Aluminum is the best choice for what a good Truss Screed is manufactured out of, they are…

-

- Lightweight... aluminum allows you to mobilize and assemble the system much easier. In general, steel is three times heavier than aluminum. That makes aluminum screeds much easier and less labor intensive to transport and set up.

- Transfer of VPM... (Vibrations Per Minute) Aluminum is much more efficient than steel at transferring VPM, Morrison screeds for instance produces 14,000 VPM’s.

- Aluminum does not rust... that's an easy one, steel does.

- Easy to clean...Anodized aluminum is much easier to clean than steel.

- BOLTED DESIGN… Some screeds are welded together making it difficult to repair damaged sections, and making it necessary to replace whole sections. Look for a system that is bolted together and you can easily just replace the damaged part, not the whole section.

- OFFERS A VARITY OF SUB-SECTION WIDTHS… this allows you to mix and match sup-sections to achieve the optional operating width configuration for any project.

- ADAPTABLE CONFIGURATIONS... A system that offers a variety of end options, for curb adaptors, bridge parapet adaptors, etc.

- SYSTEM THAT IS AVAILABLE IN BOTH SELF-PROPELLED AND MANUAL DRIVE OPTIONS… Some contractors prefer self-propelled drive systems and others prefer a manual drive system. So. Look for a manufacturer that gives you both options.

- POWER SOURCE… make sure the gas engine is a known, dependable brand, nothing worse, and costly than being all set and ready to go and the engine won't start

- EASILY ADJUSTABLE… make sure that the system you choose can easily adjust. So you are able to create either a “Crown” or a “Valley” or flat surface across the width of your pour

- VIBRATION SYSTEM… this is a good point not often thought about, different manufacturers use a variety of methods to deliver VPN’s effectively, is it a simple, robust system? Inspect their bearings and shaft system, some Truss Screeds are designed to continue to operate even with a percentage of bearings that have failed, this is critical because it allows you to complete the project even if you loose a bearing

- EASE OF ASSEMBLY & DISASSEMBLY… some systems are overly complicated, get one that is easy for you and your workers to understand so you don’t spend a lot of extra time on site trying to “Figure it out”

- ABILITY TO SPAN GREATER WITHTS… always check to see how wide a pour is possible with the system being looked at

- BUY EQUIPMENT MANUFACTURED BY A REPUTABLE, LONG-TIME MANUFACTURER… that's just common sense... it’s a good idea to buy a system that is manufactured by a company that has been manufacturing Truss Screeds for a long time. Some manufacturers have been manufacturing their systems for decades. A couple reason this is important... First, is that they have had many years to improve their system... And second, if they have been around for years, they are likely to still be around in 5 – 10 years when you need customer support, parts, or to purchase additional sections.

These are the 11 features to look for that make a great Truss Screed. as mentioned earlier, do your homework, get a Varity of opinions, read other articles like this one. And I think what is really important is talk to other contractors that use Truss Screeds and get their opinion.

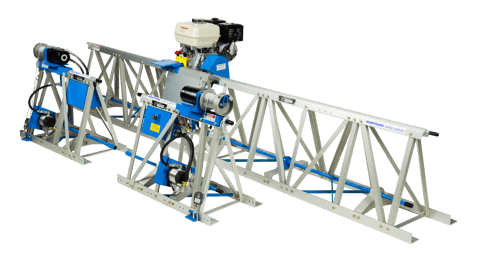

BARTELL GLOBAL'S MORRISON'S TRUSS SCREED

OK, you may notice that it is quite the coincidence that all the things to look for in a great Truss Screed just happens to be the features found on

Bartell Global's Morrison Truss Screed System

Why is that? it is because we have been manufacturing the Truss Screeds for decades! And, through all those years, all the design and engineering improvements, many if those as a result of feedback we have received from our contractors, we are proud to have developed a very robust, contractor friendly system that is highly effective, easy to construct, operate and yes, when necessary, really easy to repair. Making the Morrison Truss Screed a great system to consider.

CLICK HERE FOR MORE INFORMATION ON BARTELL GLOBALS MORRISON TRUSS SCREEDS

if you are looking for additional information on Truss Screeds give either us here at Bartell Global or one of our local distributors a call and we can with your decision making process.

By

By