If you have ever had concrete placed at your house, possibly a patio or a walkway, you probably watched them “Screed” the concrete using either a 2X4 (Hopefully a fairly straight one) possibly an Aluminum or Magnesium board if they wanted to get fancy, and they would level it or “Strike it off”. also, sawing the screed board back and forth to remove air and consolidate the slab. This method in most cases is great for residential purposes... What you probably did not see is them using a Powered, Vibrating, Truss Screed. The reason you don't is because it is just not necessary on most residential applications. But…

When placing concrete that must perform at its highest-level, like road beds and commercial structures, contractors will use a Powered, Vibrating, Truss Screed as one of the first steps in the placement of concrete. There are several benefits to a concrete slab when it has been screeded with a Vibrating Truss Screed when placed. These benefits are...

- Truss screeds make “Striking off” the wet concrete much easier

- Vibrating Truss Screeds effectively and quickly consolidate the concrete to a depth of over 12" locking the aggerate in place

- Truss Screeds remove air from the wet concrete, air pockets weaken the concrete and gives a place for water to collect. and in cold environments, these water filled now frozen voids damage the slab because water expands 9% when it freezes

- Manny Truss Screeds can be adjusted so that the concrete pour will either have a “Crown” like roadbeds have, or a consistent level surface like many commercial applications require, or even a “valley” in the slab sometimes needed for water direction and runoff

- When using a Truss Screed, you can achieve a much higher FF (Floor flatness) reading as well as adjusting for FL (Floor level) compared to other methods

- You can effectively screed thicker concrete with a “Slump” as low as 2", delivering a concrete slab with a much higher PSI reading

So, while on residential projects in general, Truss Screeds in most cases are not necessary. they are definitely a necessary step for applications where a high level of performance is required from the concrete being placed.

A great Truss Screed to consider...

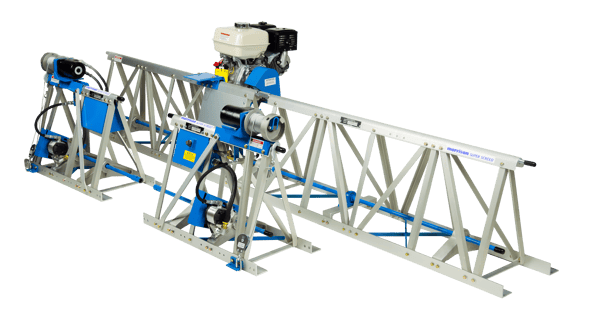

If you’re considering a Truss Screed, at Bartell Global, we manufacture a really well designed line of screeds from a one-man screed, the Uni-Screed to our Morrison Truss Screeds, both the standard truss screed with a working width of up to 40 feet to the Super Screed with a working width of 80 feet. some main features are...

- anodized aluminum construction... the reason that this is such a great feature is... it won't rust, much lighter than steel trusses, easier to clean, aluminum transfer's VPM (Vibrations Per Minute) more efficiently than steel, over 1,400 VPM's

- unique and patented shaft and bearing design... allowing you to operate the machine, finish your pour even if up to 20% of your bearings were to fail

- Bolted together design... no parts are welded making it easy to repair damaged sections instead of replacing whole sections

CLICK HERE FOR INFORMATION ON BARTELL GLOBALS MORRISON TRUSS SCREED

Also, contact one of our many distributers for additional information. Or, contact us directly at Bartellglobal.com for additional information on our Truss Screeds or any of our other related equipment.

By

By